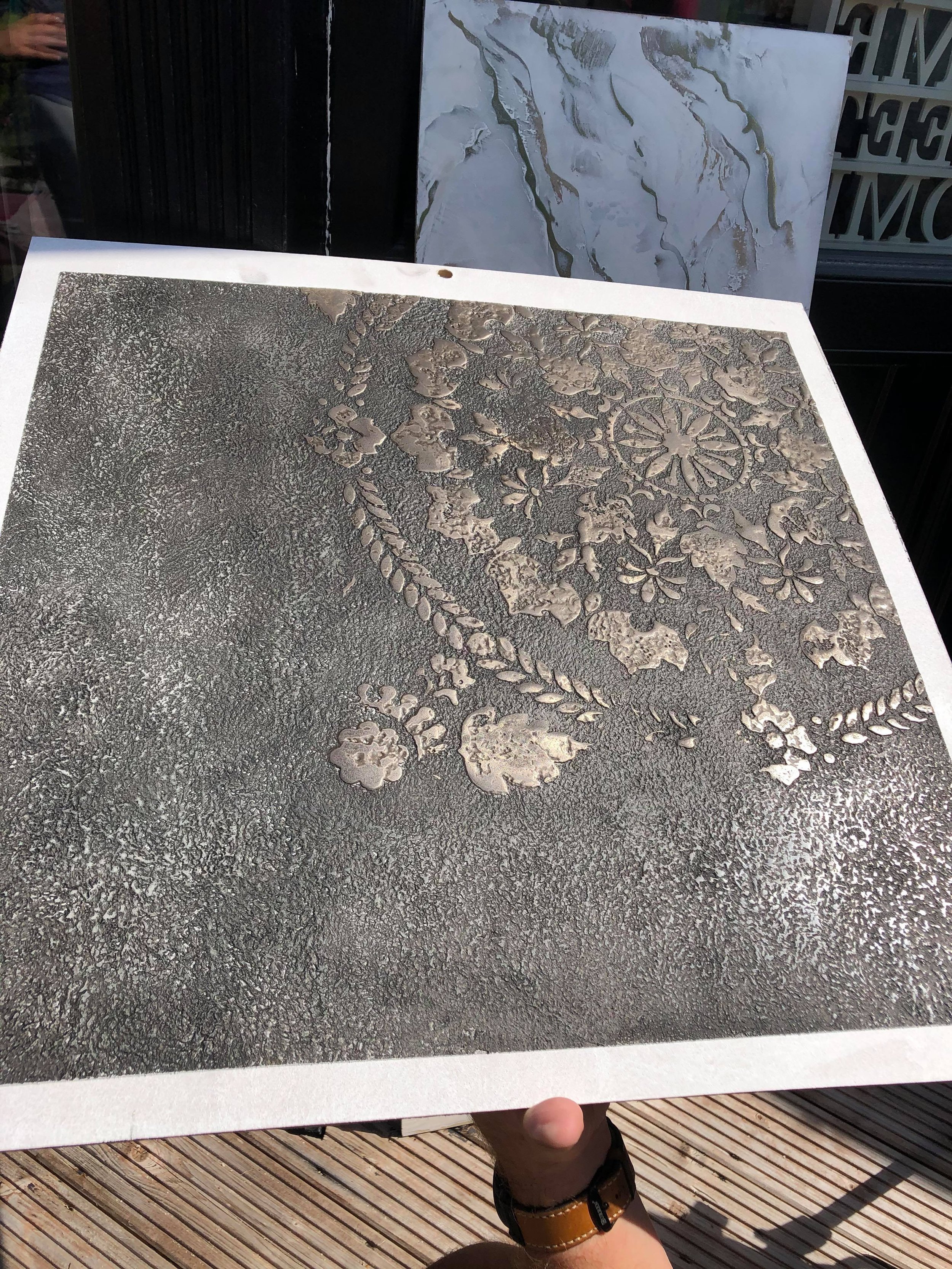

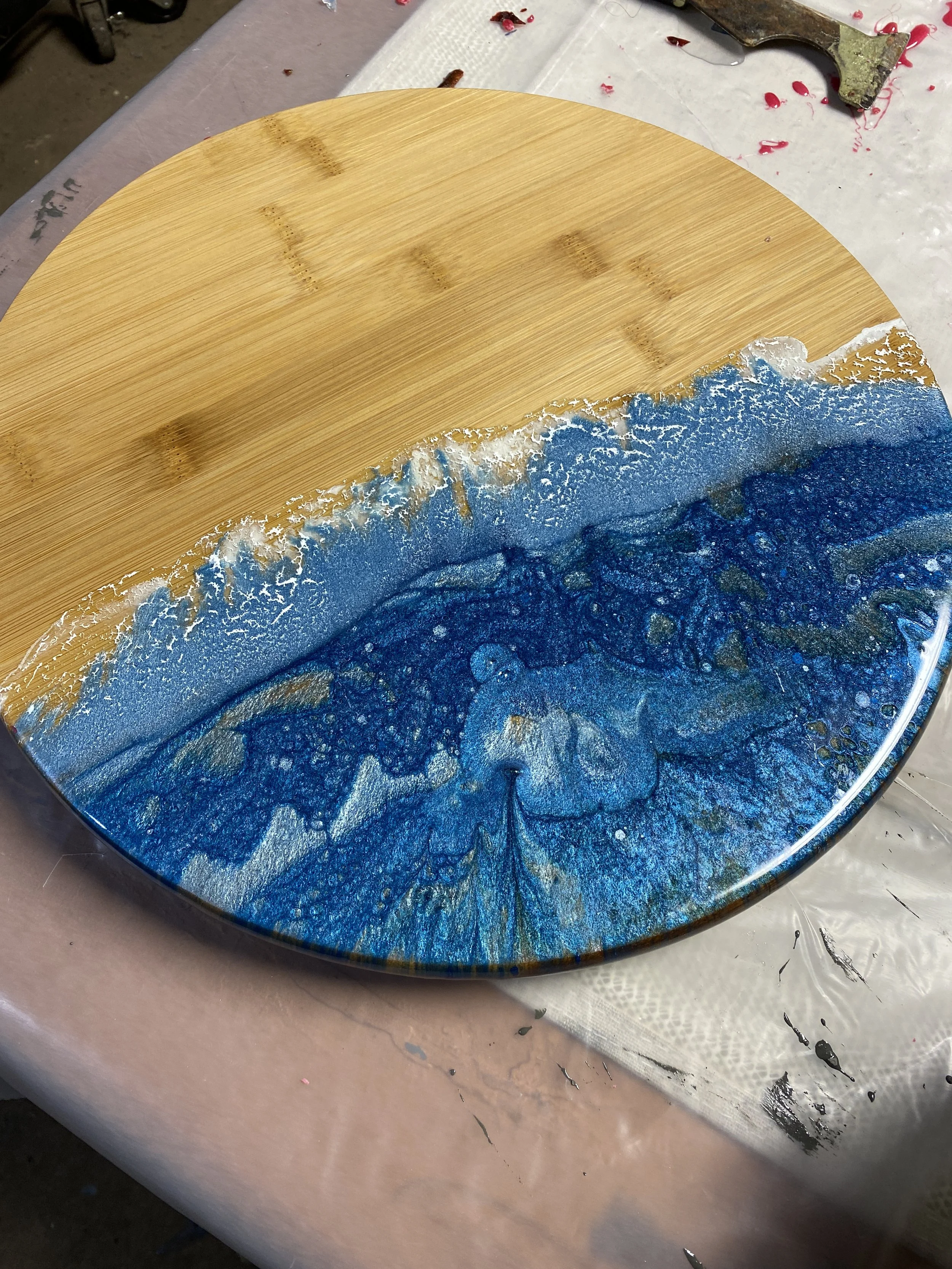

Learn all the necessary skills to successfully apply and finish liquid metal coatings.

With our Training Program, you will learn all application steps, from preparation and polishing and clear coats to marketing tips.

We offer both water and solvent based liquid metal training.

What is the difference?

You can polish the solvent to a higher sheen. Some think it’s easier to work with and some don’t. The solvent is “hardier” than the waterbased. Think of the difference between enamel and acrylic. There is slight movement/softening in the acrylic in the heat but that is not a bad thing. Apart from the high sheen and possible ease of working it is purely a matter of taste and how you plan on incorporating it into your business.

Hands-on training

Virtual update classes

Private and semi-private classes

“Thank you Kathy for the great class and for your continual epic efforts to keep us all learning and staying on the cutting edge of products, design and marketing. During these difficult times with Covid, it was so nice to be “back at it...creating”. It is a remarkable product. It’s easy to maneuver...a little goes a loooooong way! The possibilities are quite endless. As was proven in our class. People knocked design out of the park. Be excited for the next class. Be excited!”

— Jayne Habicht

Sample schedule depending on which class you choose.

Day 1

Introduction to liquid metals (history, uses)

Discussion on priming options

Discussion on application methods, including troweled, brushed, rolled, sprayed

Demonstrations

Discussion on sanders, sanding and polishing methods and sanding disc types

Execute your own samples using the water-based binder.

Day 2

Discussion and hands on using wax and clear coat

Marketing and pricing liquid metal

Every effort is made to bring in a representative from Mirka, Festool or SurfPrep so you can get a feel for an extraction system, if you choose to use one.

Day 3 Optional and varied offerings at some location dates

Discussion and usage of solvent binder, including the thinner and texture

Discussion and usage of various patinas, special effects and mixtures

Niche marketing

We will create a finish on an actual surface. Past projects have included an elevator door, countertop, door, and sink.